Eurofluid Examines the Effects of Air in closed systems

The Effects of Air inside Heating Systems – Or is it just a load of hot air?!

Henry’s Law (1803) states that gasses are soluble in water, the respective volume of gas dissolved is dependant on the pressure and temperature of the water.

As temperature decreases, and or pressure increases the volume of dissolved gas increases.

In sealed heating systems free and dissolved air cause a number of problems. In an around the circulation pump, micro-bubbles form on the pump suction as a result of localised pressure drop. This directly affects the liquid displacement of rotary pumps, reducing the flow capacity and therefore the efficiency of the system.

The presence of micro-bubbles and dissolved gas can reduce the liquid displacement of a pump by 10 to 45%. These effects are also seen on balancing valves giving unrepeatable results. This significantly increases the commissioning time associated with precision equipment e.g. Chillers.

Free air, along with localised micro-bubbles cause noise in systems, often amplified through unrelated equipment e.g. expansion vessels. This acoustic vibration also affects mechanical valves, seals and pumps reducing the component life and alters the perception of the end user as to the suitability of the system as a whole.

Flamcovent Clean Smart F Flexbalance (Plus) Flamcovent Clean Smart Eco

A common misconception in the industry relates to air and ways to combat the effects of free air. On discovering micro-bubbles in a system some engineers increase the overall pressure of the system. Whilst micro-bubbles will no longer form, the dissolved gas percentage increases. This in turn continues to have an effect of the liquid displacement of the pump and also increases another complication associated with air in sealed systems, corrosion.

Materials of construction come under more scrutiny in today’s construction market as price becomes a governing factor in securing project work. Carbon steel pipe-work is common place and extensively used in HVAC systems. Heat, oxygen and water are the three ingredients in corrosion. Water and thermal transfer are required, the oxygen is not. Effective removal of dissolved gas, especially oxygen will prevent or slow the effects of corrosion.

Corrosion is a process that is difficult, if not impossible, to stop once it has begun. Corroded metal breaks off and becomes water borne debris. This debris clogs heat exchanger channels, fouls filters and causes excessive wear in circulating pumps.

Pure clean water, with reduced or eliminated dissolved gas, is the ideal state for thermal transfer providing the optimum conditions in a repeatable manner.

Myths on high velocity…

Within the industry there are various units that claim a high velocity, generally 2 m/s or greater. The ability of such units to effectively remove micro-bubbles is limited. The micro-bubble, by definition, is small and lacks the buoyancy of large bubble to rise to the surface. The micro-bubble, coupled with a high velocity guarantees that the bubble is carried around the system, never being allowed to rest or coalesce (join with other micro-bubbles forming a larger bubble that will break free of the water flow) in a particular area.

The high velocity units on the market tend to rely on the centrifugal principle, which is more suited to large air bubble removal, never allowing the micro-bubbles to join or collect. Unfortunately the micro-bubbles are not efficiently collected in this manner.

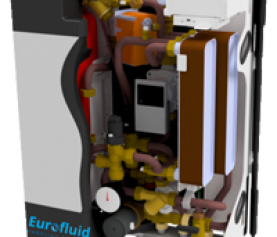

The Europak Flamcovent unit offered by Flamco has been independently tested and verified to show that a maximum velocity of 3.0 m/s, coupled with the patented PALL rings, is an effective and efficient method for both large bubble and micro-bubble removal.

The cross section presented to the flowing water has no clear path through, all the water is diverted by the PALL rings and essentially slows within the larger diameter of the unit. The increased surface area and hydrofoil action of the PALL rings allow further pockets of lower pressure to develop accelerating the deaeration process and promoting coalescence on the large stainless steel area of the PALL rings. The automatic air vent on the top of the unit is then simply used to allow the now larger bubbles to discharge to atmosphere.

Europak Flamcovent Clean Smart systems remove micro-bubbles by essentially filtering out the bubbles. A large surface area is presented to the water as it flows through the equipment. The micro-bubbles adhere to the smooth surface and join together into larger bubbles in a process called coalescence. The larger bubbles do not have any momentum to be carried through the unit and simply float away to the automatic air vent located at the top of the equipment. This equipment is ideally suited to heating systems and is located directly after the heat generating equipment on the suction side of the pump. This makes the best use of Henry’s Law combining the reduced pressure on the suction side of the pump along with the highest temperature in the system.

The Europak PSD (Pressure Step Degasser) equipment is ideally suited to chilled systems. This equipment samples water from the system in a side stream manner, minimising the effect on system pressure or flow. The sampled water is then subjected to a vacuum, dramatically ‘stepping’ the pressure down making full use of Henry’s Law relating to pressure. With the reduction in pressure, the water sample boils within the cylinder, the dissolved gasses are liberated and as the equipment completes its cycle the liberated gasses are pushed out of the automatic air vent.

Europak Flamcomat systems can balance the pressure of heating or chilled systems, taking up the associated expansion and degassing the system as a controlled process. The system pressure is balanced to within +/- 0.2bar though the complete operating cycle.

Eurofluid believe that an optimum solution can be offered for all systems, whether balanced expansion, air removal, dirt removal or combinations of these. If in doubt just ask.

Please check out our brand new website for further details – www.euro-fluid.com

Europak Flamco Flexfiller Plus Larger Systems Europak Flamcomat

Combined Pressurisation Unit & Vacuum Degasser Combined Pressurisation, Vacuum Degasser

![]() Effects Of Air In Sealed Systems – Article EF

Effects Of Air In Sealed Systems – Article EF