The heat interface unit key features:

The heat interface unit key features: Moulded EPP Insulation

One way to reduce the rate of heat loss is to insulate. The range of Thermal Integration HIUs make use of highly engineered EPP Expanded Polypropylene moulded enclosures that encase individual components supporting assemblies and preventing any heat bridging to the environment Heat losses of under 2W are available making the drain on energy use less than 1 pence per day.

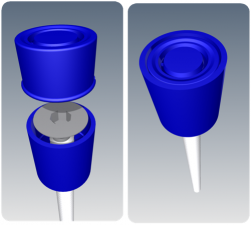

The heat interface unit key features: Heat Meters Security

Components of the heat interface unit key features such as heat meters and security valves require security measures to be fitted to the pipe work connections, to prevent their removal from the system without trace. The Meter Security Clips come in various sizes and provide a permanent security fixing that prevents access to connections without breaking the seal permanently.

The heat interface unit key features: Economy Mode

Another way to reduce losses is to allow the system to go cold when not in use The range of electronic HIUs provide an optional Economy Mode whereby the HIU will go cold after one hour of inactivity significantly reducing energy consumption further Sterilisation cycles ensure that the system is never left cold for extended periods to prevent a build up of Legionella bacteria.

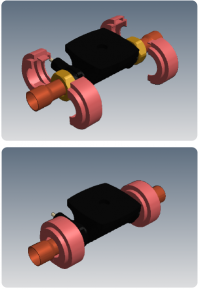

The heat interface unit key features: Advanced Heat Exchange

The final way to reduce heat losses on the district system as a whole is to run the network at lower temperatures typically 65C flow and 35C return with very low temperature drop across the plates. Multi-pass heat exchangers are used to ensure these types of temperature drops can be achieved while maintaining turbulent flow across the range of outputs.

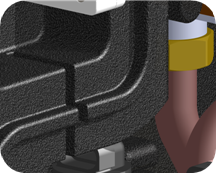

The heat interface unit key features: Security Clips

To simplify the process of securing bolts and access points on HIUs, we make use of unique moulded security clips and caps that once assembled, makes it impossible to access a bolt head or connection nut without breaking the cap.

To secure casings, and any bolted on components that one would like secured, we use a Bolt Security Cap. Bolts are inserted through the lower part of the security cap assembled, and screwed into position. The upper part is then pushed into the lower part until it locks, at which point the cap cannot be removed, and the screw head cannot be accessed.