SONDEX Plate Heat Exchangers

Most Extensive Plate Heat Exchanger Portfolio!

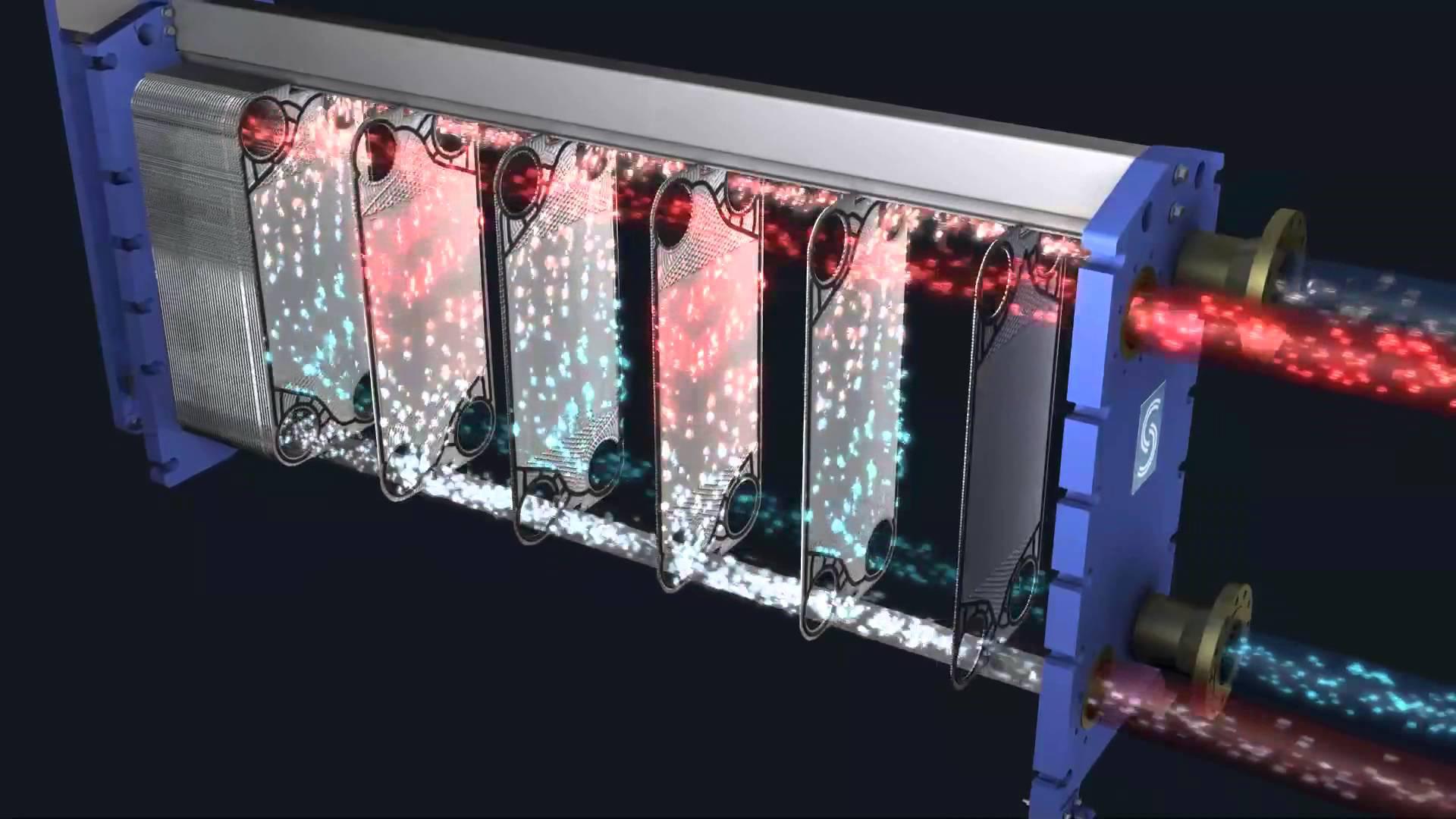

With the most extensive plate heat exchanger range, Sondex has got the optimal technical solution for any possible task. Connections from Ø15 to Ø650mm covering a liquid flow range from 50 l/hour to 2800 m3/hour. The unique inlet designs and plate patterns ensures a high thermal efficiency and heat transmission for any given pressure drop. Sondex delivers standard, copper brazed, semi-welded and all-welded plate heat exchangers as well as customized heat transfer solutions for any task.

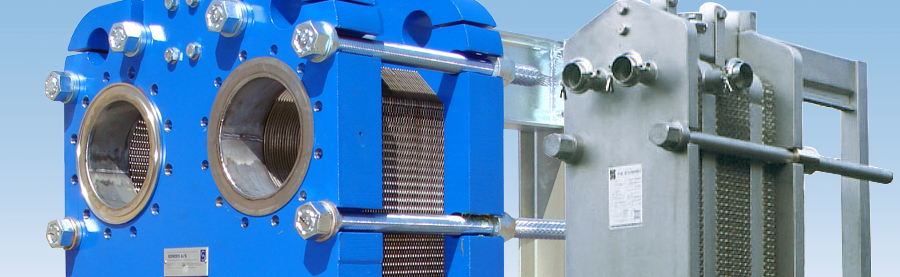

Standard Plate Heat Exchangers

Sondex delivers standard plate heat exchangers as well as customized heat transfer solutions for any task. The Sondex plate pattern is designed to solve a variety of different heat exchanger applications.

Advantages

- The plates and plate patterns are constructed to obtain a high thermal efficiency with a low pressure drop

- There are two pattern designs available with different pressing angles giving respectively high/low turbulence flow, dependant on the given selection

- The inlet channels allow for maximum strength in the inlet area, whilst maintaining minimum of contact points, reducing blockage at the flow distribution zone

- The inlet design ensures even distribution of the liquids across the heating surface

- The gasket is placed in a dedicated retaining gasket groove. This secures the elasticity of the gasket even after a long time of compression

Free Flow Plates

Sondex “Free Flow” plates are used for liquids containing solids, particles, fibres or high viscous products. The plates are commonly used in the pulp & paper industry, in waste water treatment plants, the sugar industry, juice production, grain based ethanol production, heat recovery systems and for special tasks where standard plate heat exchangers usually will block.

Advantages

- Suitable for products with solid particles

- No metal/metal contact in corner holes/inlets

- Inlet area designed for optimal turbulent flow

- Up to 20 mm constant plate gap

- No dead spots on the plate

- Suitable for Cleaning In Place

- High thermal transmission

- Even distribution

- Low pressure drop

Sonder Safe Plates

The Sondex Sonder Safe system consists of two thin flow plates pressed together. The unique Sonder Safe plates means that should there be a leak in one of the plates, the media will run out between the plates, allowing the leak to be seen from the outside.

The “Sonder Safe Plates” are available in two versions – an industrial and a sanitary design

Advantages

- Allows leaks to be seen from outside between the two plates

- Prevent co-mixing of products whilst providing a warning system

Brazed Heat Exchangers

Sondex brazed plate heat exchanger consists of a number of thin acid-resistant precision stamped stainless steel plates with copper brazed gaskets.

The plate packs are brazed with two end plates and connections. Vacuum brazing at extremely high temperatures provides a permanently sealed heat exchanger. The final result is a strong and compact plate heat exchanger with extremely high heat transfer capability.

Applications

- Heating and cooling of clean liquids

- Evaporators and condenser units

- District heating and ventilation

- Solar heating and air conditioning units

- Heating pumps and heat recovering units

- Temperatures from minus 180°C. up to 200°C

- Operating pressure can be as high as 35 bar.